Uchida's Powerful Technology Supports

World-Class Automobile Production

Japanese automobiles are proud of the best level of performance in the world.

The superior quality and performance for which they are known

are firmly supported by advanced Japanese die technology,

which rands among the best in the world.

Since its establishment in 1934, Uchida Co., Ltd. has led the Japanese die industry

with cutting-edge technological capabilities.

Today, Uchida not only designs and manufactures dies,

but also operates as a general engineering company to support all phases of automobile production,

playing an important role in both the Japanese and the world's automotive industry.

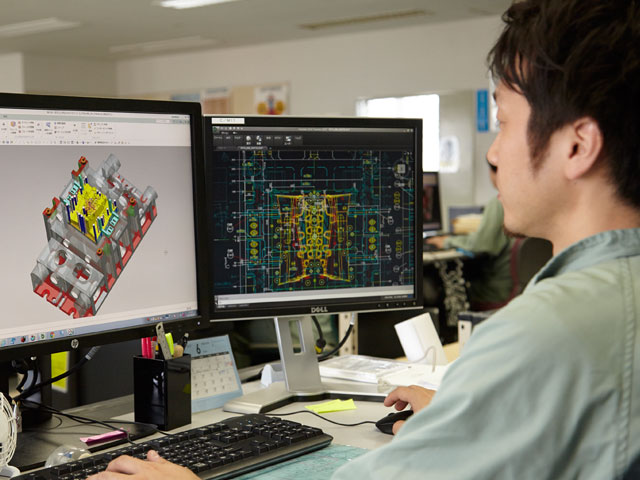

Digital Engineering

3D CAD design is essential for the design of increasingly complex dies. Simulations communicate design ideas better than words.

Knowledge and Skills

Every day experienced engineers teach young engineers. Demonstration and emulation impart knowledge and skills acquired through long experience and intuition.

Fostering Leaders

Skills transmission is vital for competitiveness in die manufacturing and for maintaining originality. At the same time, we are fostering leaders who understand everything there is to know about die technologies.

Teaching the Next Generation

Uchida's engineers give lectures to graduate students at the Kyushu Institute of Technology and at other educational institutions.We also hold technical training seminars at our factory. In these ways we teach a new generation about die technologies,contributing not only to our own development, but to the advancement of the die industry as a whole.

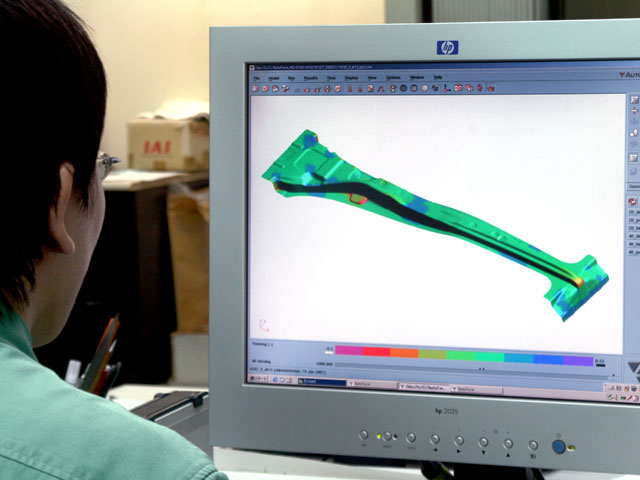

Developing New Technologie

In 2002, Uchida developed the world’s first dies capable of mass-producing automobile center pillars made of ultra-high-strength steel (SPC980). By pioneering new press die technologies for mass-producing parts made of tough, hard materials previously difficult to process, Uchida has maintained its position as the industry leader.

Next-Generation Endeavors

Cars will evolve by shifting from the use of metal parts to the use of strengthened plastic parts. With an eye on the future of automobiles, Uchida seeks business development through new die technologies.

COPYRIGHT © UCHIDA. ALL RIGHTS RESEVED.

PAGE TOP